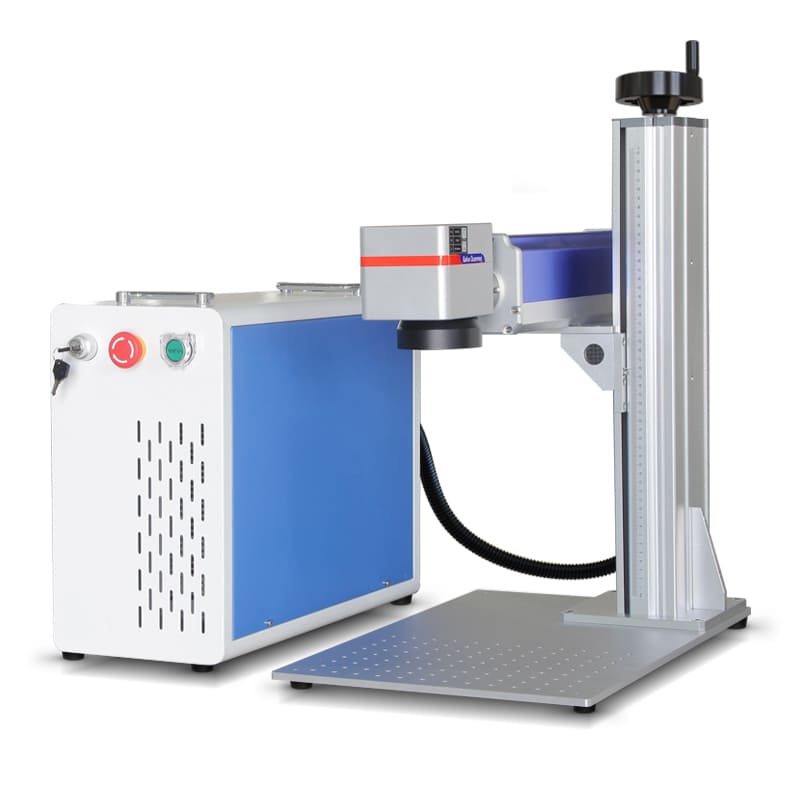

Visual Positioning Double Station Fiber Marking Machine With Ccd Camera

- 20w 30w 50w 60w 100w Laser Power

- Raycus Max JPT Bwt IPG Laser Source:

- Marking on Metal Materilas, like SS CS Aluminum Gold Sliver Copper etc

- Working Area: Double Station Custom Size

All parameters can be customized to fit the customer's needs

PRODUCT CATEGORIES

NEED CONSULTATION?

Share your idea, We’ll find solution for you within 24 hours

Visual Positioning Double Station Fiber Marking Machine With Ccd Camera Introduction

The Visual Positioning Double Station Fiber Marking Machine is an advanced laser marking system equipped with visual positioning technology and featuring dual workstations for increased efficiency and productivity.

Visual Positioning Technology: Integrates high-resolution cameras and advanced image processing algorithms to accurately identify and position workpieces for precise marking.

Visual Positioning Technology: Integrates high-resolution cameras and advanced image processing algorithms to accurately identify and position workpieces for precise marking.

Dual Workstations: Allows marking on two separate workpieces, maximizing throughput and reducing idle time.

The applications of fiber laser marking machines are diverse and extensive. They are widely used in industries such as automotive, aerospace, electronics, medical devices, jewelry, and packaging. These machines can mark serial numbers, barcodes, logos, text, and intricate designs on various surfaces with impeccable detail. Additionally, fiber lasers are capable of marking on curved or irregular surfaces, making them versatile for different manufacturing processes.

From automotive part identification to medical device serialization, the fiber laser marking machine is an indispensable tool for modern manufacturing, providing permanent, high-quality marks with speed and precision.

What materisls dose a fiber marking machine can mark? A wide range of materials, including:

- Metals:

- Steel

- Stainless steel

- Aluminum

- Brass

- Copper

- Titanium

- Gold

- Silver

- Platinum

- Plastics:

- ABS (Acrylonitrile Butadiene Styrene)

- PVC (Polyvinyl Chloride)

- Polycarbonate

- Polyethylene

- Polypropylene

- Acrylic (PMMA – Polymethyl Methacrylate)

- Nylon

- Ceramics and Ceramic Coatings:

- Porcelain

- Ceramic tiles

- Ceramic coatings on metal

- Organic Materials:

- Wood

- Leather

- Paper

- Cardboard

- Composite Materials:

- Carbon fiber

- Fiberglass

- Composite laminates

- Anodized Materials:

- Anodized aluminum

- Some Specialized Materials:

- Silicon

- Tungsten

- Graphite

- Some types of glass (e.g., borosilicate glass)

Frequently Asked Questions (FAQ) – About Fiber Laser Marking Machines

Q:What materials can be marked with a laser marking machine?

A: Laser marking machines can mark a wide range of materials, including metals (steel, aluminum, titanium), plastics, ceramics, glass, wood, and some organic materials.

Q: What types of marks can a laser marking machine create?

A:Laser marking machines can create various marks, including serial numbers, barcodes, QR codes, logos, text, graphics, and even 3D images.

Q: How durable are the marks created by laser marking machines?

A: Marks created by laser marking machines are highly durable and resistant to wear, corrosion, and fading. They are often used for permanent identification and traceability purposes.

Q: Can laser marking machines mark on curved or irregular surfaces?

A: Yes, many laser marking machines are capable of marking on curved or irregular surfaces. Some machines feature rotary attachments or 3D marking capabilities to accommodate such surfaces.

Q: Are laser marking machines safe to use?

A: Laser marking machines are generally safe when used properly. However, operators should follow safety guidelines and wear appropriate protective equipment to prevent exposure to laser radiation.

Q: What maintenance is required for a laser marking machine?

A: Laser marking machines require minimal maintenance compared to other marking technologies. Routine maintenance may include cleaning the lens, checking and adjusting the beam alignment, and replacing consumable parts such as lenses or filters.

Q: Can laser marking machines be integrated into automated production lines?

A: Yes, many laser marking machines are designed for integration into automated production lines. They can be equipped with conveyor systems, robotic arms, and other automation components for seamless operation.

Q: What factors should be considered when choosing a laser marking machine?

A: Factors to consider include the type of material to be marked, desired marking speed and precision, available space for the machine, integration requirements, budget, and any specific features or capabilities needed for the application.

Q: What payment terms can you accept?

A: Any payment is possible for us , like Made-In-Chine on line payment, TT, LC, Western Union, Paypal, E-Checking, Master Card, Cash etc.

Q: Do you have CE document and other documents for customs clearance?

A: Yes,we have, At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/Proforma Invoice for customs clearance.

Q: When I got this machine, but I don’t know how to use it. What should I do?

We will send operation video and manual for the machines(Photos/Videos/Manual Book,etc) ,you can learn step by step. Our engineer also can do training online. If needed, we support engineer door training if you need.

Q: If i have problem during use,how to do?

A: If have any problem during use, we can provide team viewer/Whatsapp/Email/Phone/Skype with cam till all of your problems finished. We can also provide door service if you need.

Q: If some problems happen to this machine, what should I do?

A: We provide 2 years source and 1 year whole machine warranty. During the warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q: What’s package, will it protect the products?

A: We have 3 layers package. For the outside, we adopt wooden cases free of fumigation. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic film.

Q: What’s delivery time?

A: Commonly, the lead time is within 3 working days after receiving the payment.

Q: How is the shipping method?

A: As per your actual address, we support shipment by sea, by air, by truck or railway shipping way. Also we can send the machine to your office if you need.

OTHER MARKING MACHINES MODELS

RELATE PRODUCTS