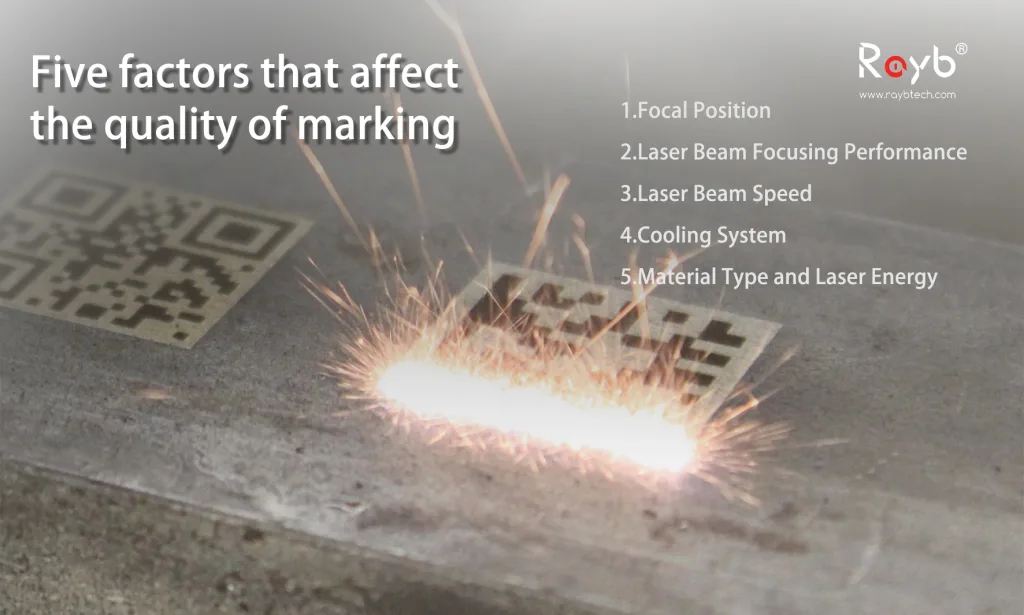

The quality of a laser marking machine often gradually decreases over time. This can be attributed to several key factors that influence the machine’s marking precision, consistency, and durability. Here’s an overview of the main factors impacting laser marking quality:

1.Focal Position

The focal position is critical for marking quality since the laser achieves maximum power and precision only when focused accurately. If the focal position drifts or is improperly set, the laser’s interaction with the workpiece will weaken, impacting the marking clarity and quality. Adjusting the oscillating lens’s height during laser operation can help achieve the strongest focus, which is typically indicated by a bright blue-white light and a distinct beep sound.

2.Laser Beam Focusing Performance

The laser beam’s focusing ability directly influences the marking quality, as a tightly focused beam concentrates the laser’s energy on a small area, allowing for clear, precise markings. Poor focusing performance results in a scattered or larger beam spot, reducing energy density and compromising marking quality. Optimal focusing places the beam waist between the spotting mirror and the target, achieving the best results.

3.Laser Beam Speed

The speed at which the laser beam moves across the material is also crucial. Faster beam movement may reduce the laser’s impact on the material, resulting in lighter or less visible markings. Conversely, slower speeds may lead to excessive heating, potentially causing deformation or over-burning. Adjusting speed based on material characteristics helps achieve consistent and high-quality marking.

4.Cooling System

Effective cooling is essential for stable, continuous marking. Without proper cooling, heat buildup can interfere with laser performance and affect the machine’s circuitry, leading to inconsistent results and increased risk of malfunction. Fiber laser marking machines typically use air cooling to dissipate internal heat efficiently, reducing the chance of overheating and improving the machine’s stability.

5.Material Type and Laser Energy

Different materials respond differently to laser marking. The texture, density, and reflectivity of materials affect how the laser interacts with their surface, and even with the same machine, marking fine lines may vary based on the material. Additionally, the laser energy applied impacts the marking’s fineness and quality; adjusting energy levels based on material properties helps produce optimal results.

In summary, maintaining marking quality over time depends on proper adjustments to focus, speed, cooling, and laser energy, along with an understanding of material-specific requirements. By routinely checking these factors, laser marking machines can deliver consistent performance for an extended period.