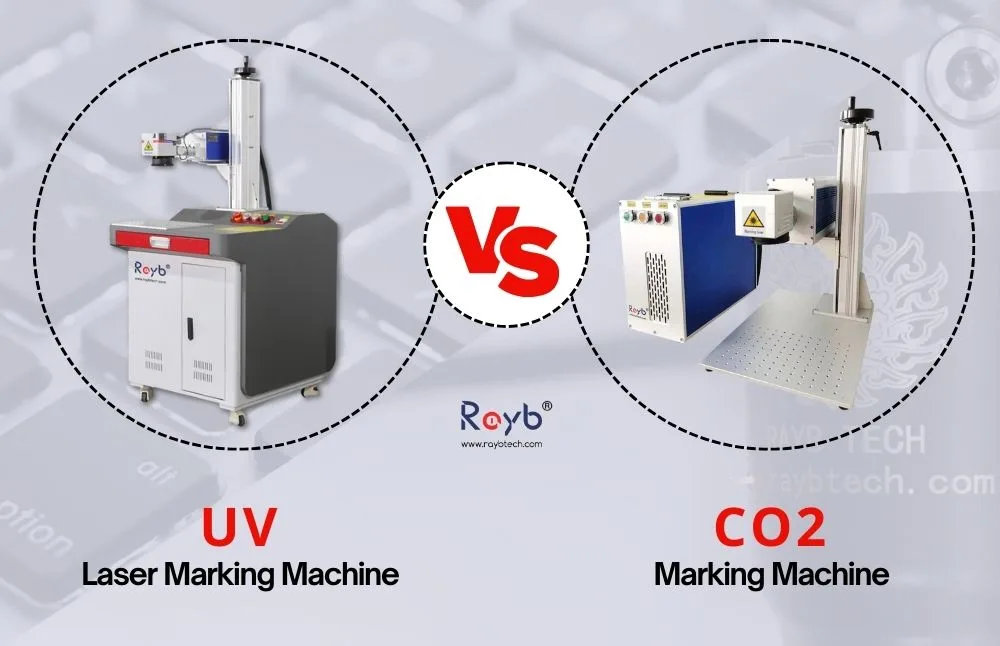

As technology advances, both UV and CO2 laser marking machines continue to evolve and adapt to various industrial applications, each with unique strengths. Let’s explore their individual advantages and how to select the best option for specific needs.

UV Laser Marking

UV laser marking operates at a wavelength of 355nm, with short pulses that produce a fine, highly focused beam. This narrow beam reduces the heat-affected zone on the material, allowing for precise marking with minimal risk of material deformation. This characteristic makes UV lasers ideal for applications requiring high accuracy, such as:

- Glass, chips, and PCB boards: UV lasers can achieve fine markings on these materials without damaging them, making them especially suitable for delicate applications in electronics and medical industries.

- Fine polymer materials: UV lasers are widely used in marking plastics, particularly where detailed and accurate marking is essential.

UV lasers offer enhanced positioning precision, allowing them to produce clear, intricate marks on even the smallest components. Market demand for UV lasers has increased over the past decade, with manufacturers shipping thousands of units annually. Although their popularity peaked around 2017, UV lasers have shown steady growth, indicating strong demand in high-precision industries.

CO2 Laser Marking

CO2 laser technology, widely adopted in the 1980s and 1990s, remains popular due to its high efficiency and reliability. Unlike UV lasers, CO2 lasers use gas to create a laser beam that leaves a lasting mark on the surface of materials. These lasers are well-suited for:

- Marking non-metals and polymers, especially plastics: CO2 lasers excel in engraving materials like wood, acrylic, and leather, where high precision is not as critical.

- Industrial applications with durable marking needs: CO2 lasers are often used for marking dates, logos, and text in industries such as packaging, food, and beverage, where high-speed and durable markings are essential.

Despite the increasing popularity of UV lasers, CO2 lasers have their own advantages. They are cost-effective, often cheaper than UV lasers of equivalent power, making them more accessible for budget-conscious projects.

Choosing Between UV and CO2 Lasers

- Precision Needs: UV lasers are the clear choice for applications requiring fine detail, particularly on glass, electronic components, and delicate materials like polymers.

- Material Compatibility: For non-metallic and polymer materials, such as plastics, CO2 lasers offer a durable and cost-effective solution, especially for applications where high-speed marking is needed.

- Cost Considerations: If cost-efficiency is a primary concern, CO2 lasers provide a powerful and affordable option, whereas UV lasers, with a higher price tag, are better suited for high-precision needs.

- Long-Term Stability: UV lasers need additional maintenance for stability and longevity. For continuous and stable operation, using a UV laser chiller is essential to maintain processing accuracy and extend the machine’s service life.

Summary

Both UV and CO2 laser marking machines bring unique advantages to the table. While the market for UV lasers is expanding, CO2 lasers remain indispensable for certain applications. Careful consideration of the specific material, application requirements, and budget will help determine the best choice for each project.