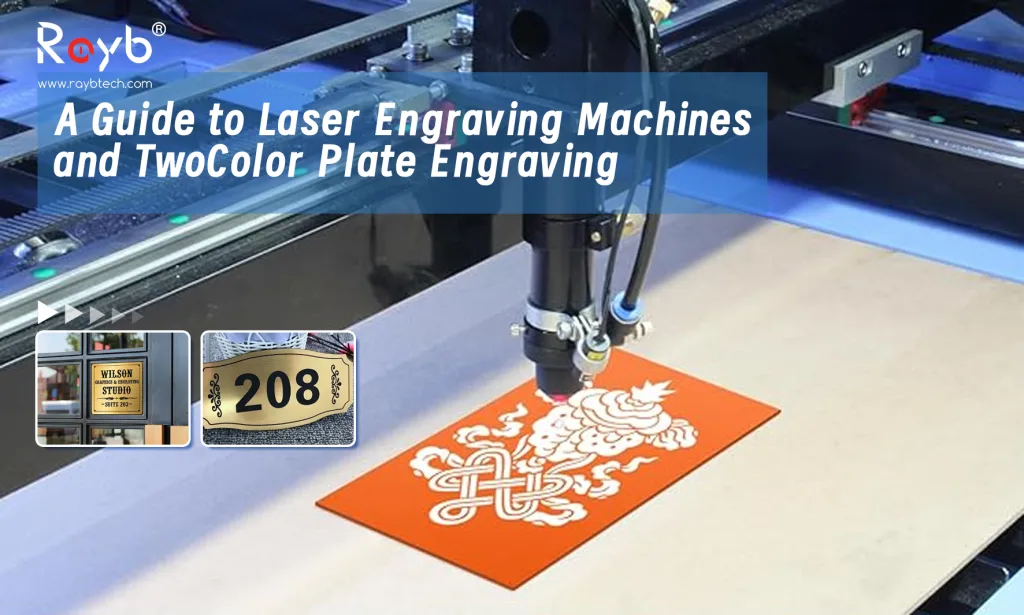

For customers and professionals in the graphic advertising industry, using a double-layer plastic sheet (also known as two-color acrylic sheets) is common. However, when purchasing and using a laser engraving machine, various challenges can arise. This article provides an overview of selecting the right laser engraving machine and addresses frequently asked questions related to two-color plate engraving.

Laser Engraving Machine Selection

1.Power

Recommended Power: For engraving two-color plates with a typical thickness of 2-3 mm, a laser machine with 80 watts of power is ideal.

2.Engraving Area

Engraving Range: If your primary focus is two-color plate engraving, consider models with an engraving area of 60×40 cm or 90×60 cm.

Larger Area for Advertising: If your work involves acrylic cutting or other plate processing, a model like the 1390 (with a 1300×900 mm working area) may be a better fit.

Stability Considerations: Generally, smaller machines experience less jitter, which can improve engraving quality. However, some machines with subpar components may still produce poor results, even at smaller sizes.

3.Focus Mirror

Focal Length: Choose a focus lens with a 50.8 mm focal length for a finer laser spot, which enhances engraving precision.

Common Problems with Two-Color Sheet Laser Engraving

Problem 1: Poor Engraving Quality – Font Details Blurred or Merged

Reason: The material of the two-color plate can significantly affect engraving quality. This issue often arises from the material itself.

Solution: Use laser-compatible double-color plastic sheets designed specifically for cutting and engraving.

Problem 2: Large Serrations in Engraving

Reasons:Machine Jitter: Excessive speed combined with the machine’s characteristics may cause jitter. Set the engraving speed to around 200-400 mm/s.

Belt and Pulley Wear: Worn-out belts or pulleys can cause inconsistencies in engraving.

Unstable Laser Output: Check the laser power supply and laser tube for issues that may cause fluctuations in laser intensity.

Problem 3: Engraving Ghosting (Double Image Effect)

Loose Focus Mirror: Ensure that the focus mirror is securely fastened.

Misaligned Optical Path: The laser beam alignment may be off, requiring recalibration.

Loose Belt: Tighten the belt to eliminate the ghosting effect.

Problem 4: White Dusty Appearance on Engraved Fonts

Reason: Excessive air blowing during the engraving process can lead to a dusty appearance on the engraved surface.

Solution: Use a regulating valve (if available on your model) to reduce the air pressure. However, do not turn off the air blowing entirely, as it helps protect the lens from burning and reduces the risk of fire during cutting.

Conclusion

When working with two-color plastic sheets, selecting the right laser engraving machine and understanding common issues can help ensure high-quality results. By choosing an appropriately powered machine, focusing on the correct specifications, and addressing potential problems, you can improve your engraving experience and deliver exceptional products for your graphic advertising needs.