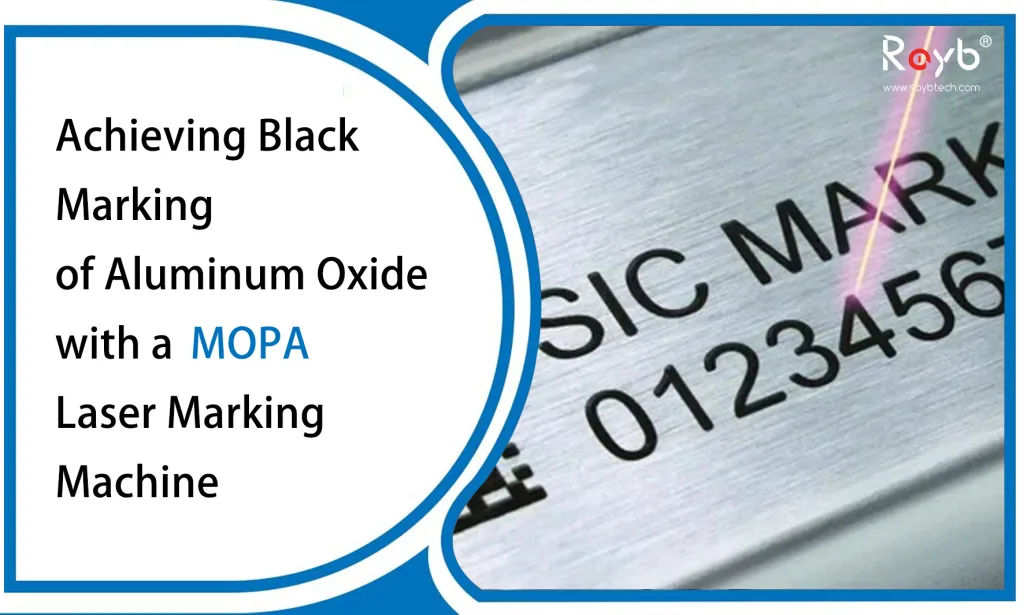

Laser blackening of aluminum oxide is a common and important application in the laser marking process, especially in industries like electronics and mobile devices. While using a standard fiber laser marking machine may result in white or gray marks, a MOPA (Master Oscillator Power Amplifier) laser marking machine can achieve the desired black mark. Here’s a detailed explanation of how to achieve black marking on aluminum oxide with a MOPA laser and why it’s the preferred technology.

Why Use a MOPA Laser?

The key difference between a MOPA laser and a standard Q-switched fiber laser lies in the pulse width and frequency adjustment capabilities:

- Wider adjustment range: MOPA lasers offer a greater range for pulse width and frequency settings.

- Shorter pulse duration: With a shorter pulse width, the MOPA laser minimizes the time the laser energy stays on the material, making it less likely to penetrate and damage the oxide layer.

- Control of the oxide layer: A standard Q-switched fiber laser can damage or break through the oxide layer, resulting in gray marks. In contrast, MOPA lasers maintain the oxide layer, producing a deeper, more uniform black mark.

For these reasons, MOPA lasers are typically used for black marking of anodized aluminum. In fact, many smartphone logos and branding marks are done using the MOPA laser blackening process on aluminum oxide.

How to Achieve Black Marking with a MOPA Laser (e.g., M6 Model)

The M6 MOPA laser is a commonly used model for this process, offering high efficiency and the ability to handle thin oxide layers or poorly treated oxidized surfaces. Here’s how to set up your machine for optimal results:

Key Parameters for Black Marking:

- Laser Frequency: Set to 600 kHz (this is a crucial parameter to ensure the right balance of energy and marking speed).

- Pulse Width: Set to 2 ns. This short pulse width helps avoid damaging the oxide layer while ensuring the laser energy is sufficient for blackening.

- Marking Speed: Adjust to 300 mm/s. Depending on the specific requirements of your material and project, you may need to fine-tune this speed.

- Filling Density: Set to 0.006. The filling density controls how densely the laser lines are packed in the mark, which can impact uniformity and depth.

Additional Considerations:

- Material Quality: The quality of the anodized aluminum (e.g., thickness and consistency of the oxide layer) will influence how the mark appears. Poorly treated or uneven surfaces may require more fine-tuning of the laser parameters.

- Uniformity: The MOPA laser excels at producing consistent and uniform black marks, even on materials with thinner oxide layers.

By using these parameters, you can achieve a deep, consistent black mark on anodized aluminum oxide without compromising the material integrity or damaging the surface layer. This process is widely adopted in industries for marking logos, information tags, and branding on aluminum components, especially for electronics and mobile devices.