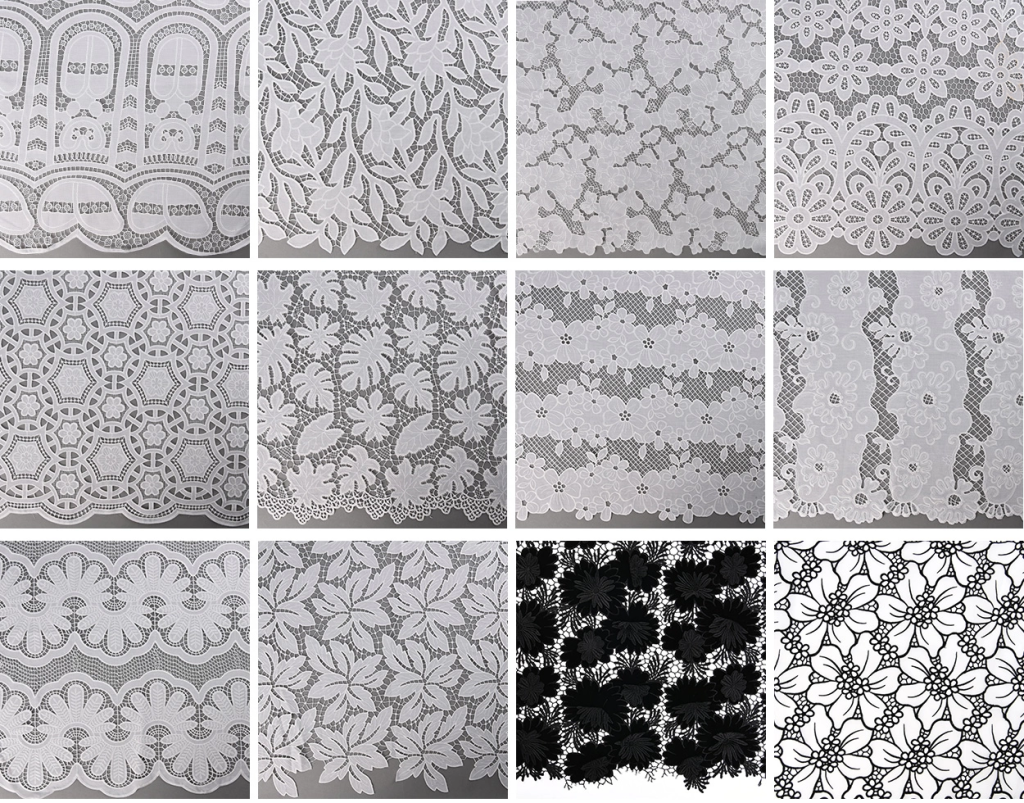

Fabric laser cutting is widely used in various industries, including textiles, clothing, plush toys, and more. One common issue when cutting white fabric is yellowing. Here’s how to address this and other common problems.

Types of Fabrics

Fabrics come in various types, each with different laser cutting effects. These include:

- Non-woven

- Polyester

- Silk

- Satin

- Twill

Common Problems in Fabric Laser Cutting

1.Yellowing and Discoloration

- Primarily seen in white cotton, dust-free cloth, and fabrics containing PC or plastic components.

2.Hardening and Scorching

- Edges of cut parts become hard and scorched.

3.Uneven Cutting Lines

- Inconsistent thickness in cut lines.

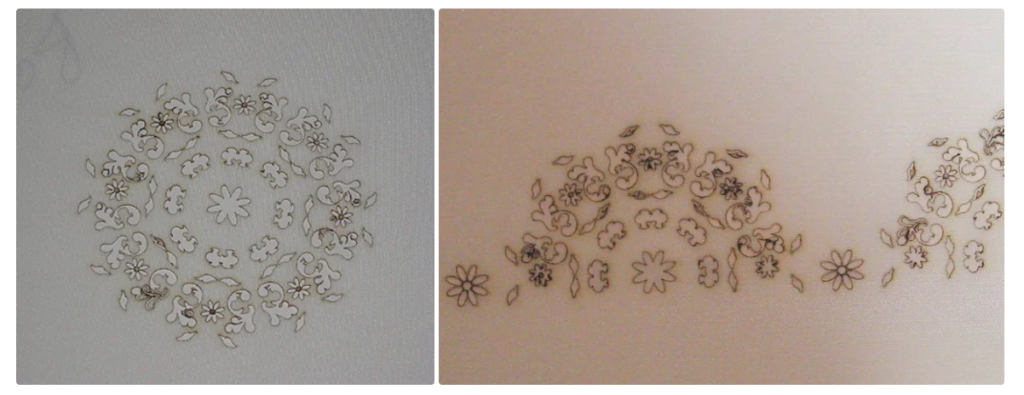

4.Cutting Graphics with Gaps

- Gaps in the cutting patterns.

Solutions to Common Fabric Laser Cutting Problems

1.Yellowing of White Fabric

- Use of Air Compressor: When cutting white cotton fabric, use an air compressor, preferably with nitrogen.

- Laser Tube Selection: Opt for a hot stab W2 or W4 laser tube.

- Light Intensity and Speed Settings: Set the light intensity to about 20-30% and the speed to 30-50 mm/s. Excessive light intensity or slow speed can cause excessive heat, leading to yellowing and hard edges.

2.Uneven Cutting Lines

- Platform Choice: The flatness of the honeycomb board affects focusing. An uneven honeycomb board can cause inconsistent cut lines. Ensure the board is flat and clean.

- Reflection Issues: Strong reflections from the feeding platform can cause uneven cuts. Clean the base plate regularly and adjust the corner light intensity.

3.Not Cutting Through

- Base Plate Cleanliness: A dirty honeycomb base plate can hinder cutting efficiency. Clean it regularly.

- Feeding Platform Design: Ensure the feeding platform is well-designed to avoid strong reflections.

4.Sample Testing

- Due to the thermal processing nature of laser cutting and the diverse composition of fabrics, it’s not always possible to completely eliminate yellowing. Customers with specific edge requirements should conduct sample tests before purchasing the machine to confirm the cutting effect.

By following these guidelines, you can minimize common issues in fabric laser cutting and achieve better results. Always test your settings and machine configuration with sample cuts to ensure optimal performance.