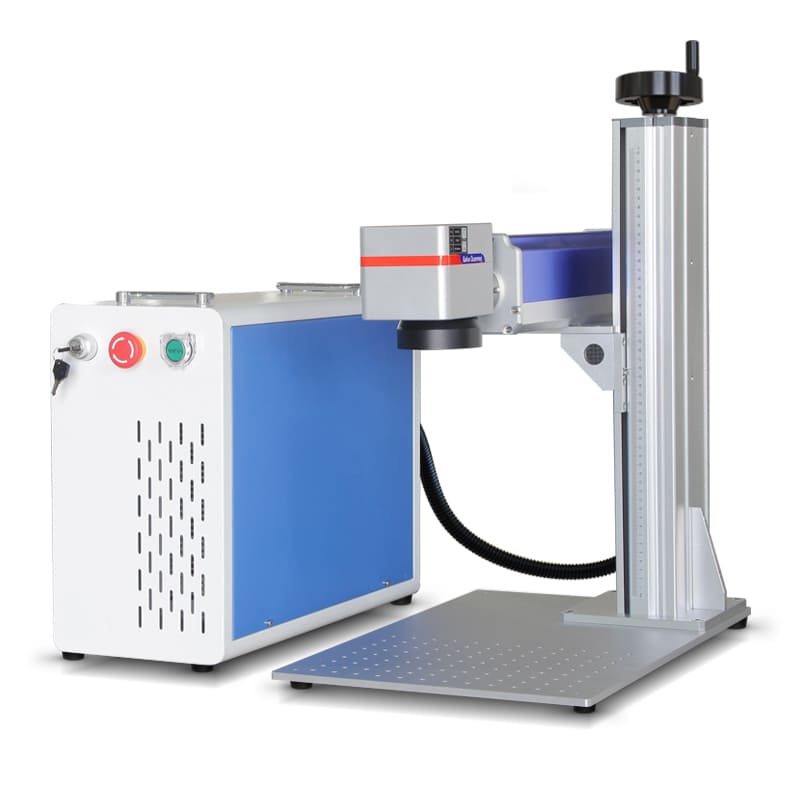

1000w 1500w 2000w Handheld Laser Welding Machine

- Laser Power: 1000w 1500w 2000w

- Laser Source: Raycus/Max/JPT/Bwt

- Welding Materials: SS CS Aluminum Galvanized Sheet

- Size:101*50*87 cm

All parameters can be customized to fit the customer's needs

PRODUCT CATEGORIES

NEED CONSULTATION?

Share your idea, We’ll find solution for you within 24 hours

Handheld Laser Welding Machine Introduction

Laser hand-held welding is a new type of welding method.

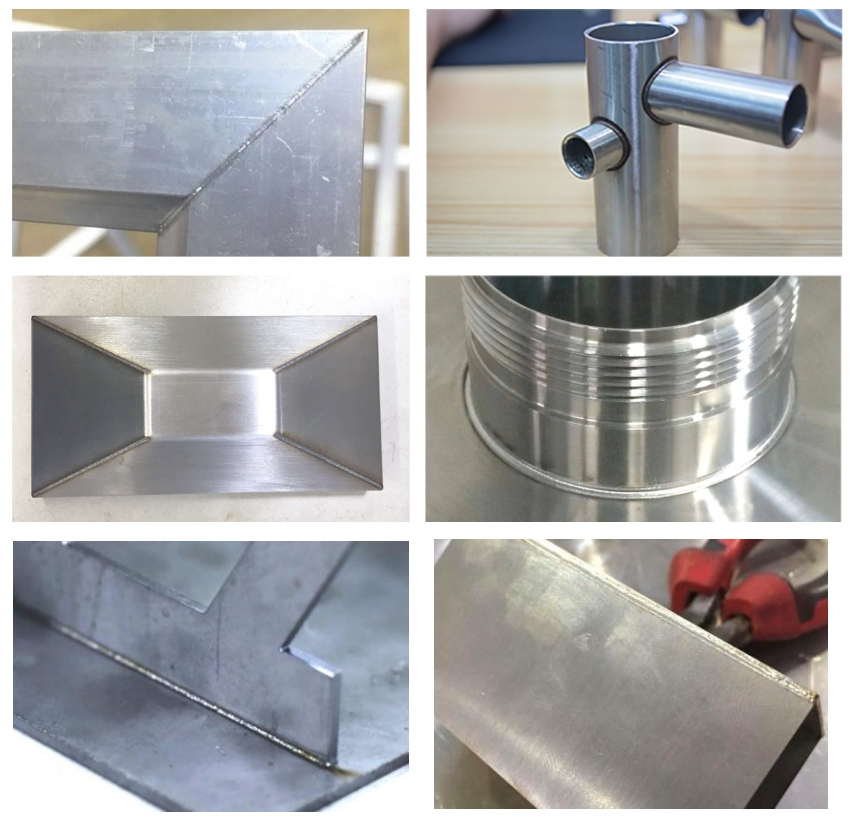

It is mainly aimed at welding thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealing welding, etc.

The width of the weld is small, the heat affected zone is small, and the deformation is small.

The welding speed is fast, the welding is smooth and beautiful, there is no need to handle or simply handle after welding, the weld quality is high, there is no air hole, it can be accurately controlled, the focus photoelectric is small, the positioning accuracy is high, and it is easy to realize automation.

Advantages of Handheld Laser Welding Machine

Integrated design with a sleek structure and high-precision beam for optimal performance.

The handheld welding head features a 1000/1500/2000 watt fiber laser source, providing flexibility for outdoor welding.

Remarkable welding speed, 2-10 times faster than traditional methods, saving at least 2 welders annually.

Smooth and aesthetically pleasing welding seams with no scars or workpiece deformation. This eliminates the need for subsequent grinding, saving time and costs.

Handheld welding gun allows for welding at any position and angle, enhancing operational flexibility.

No welding table required, compact footprint, and adaptability to various welding products and shapes.

Cost-effective welding solution with low energy consumption and minimal maintenance costs.

Facilitates easy spot welding, stack welding, splicing, and continuous welding.

Incorporates multiple detection and protection measures to prevent faults caused by external factors or misuse, ensuring long-term stable operation.

Utilizes high-quality fiber laser beam for increased welding speed, aspect ratio, and strength.

Enables remote welding through optical fiber transmission, easily adaptable to automatic welding workbenches, manipulators, and assembly lines.

Simple integration with various input and output signals for seamless automated and assembly line production.

Pollution-free solder joints with weld strength and toughness equivalent to or stronger than the base metal.

User-friendly operating system that is easy to learn and operate.

Compared with Traditional Welding

Traditional Welding | YAG Laser Welding | Fiber Laser Welding | |

Heat effect to workpiece | Very high | low | Low |

Deformation of the workpiece | Big | Small | Small or No |

Bond stength to base metal | General | Good | Very good |

After-treatment | Polishing | No need or rarely to polish | No need or rarely to polish |

Welding speed | General | 2 times Traditional Welding | 2-10 times Traditional Welding |

Consumables | More | Less | Less |

Operation difficulty | Complex | General | Simple |

Operation safety | Unsafe | Safe | Safe |

Environmental pollution | High | Less | Less |

Welding fault tolerance | Good | Not good | Good |

Swing welding | No | No | Yes |

Spot width adjustable | No | No | Yes |

Welding quality comparison | Different | General | Very good |

Handheld laser welding machine can be used to weld stainless steel, carbon steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, and can also be used for welding between various different materials, including copper-brass, titanium-molybdenum, titanium-gold, nickel-copper and so on.

Laser welding is mainly applied to welding of thin-walled materials, precision parts, etc.. It can realize spot welding, splicing welding, sealing welding, surfacing welding and so on. It has small thermal deformation, beautiful and flat welding seam, high welding quality, and no need for secondary grinding treatment. The welding of metal materials can completely replace the traditional argon arc welding and electric welding.

Handheld laser welding machine adopts handheld oscillating welding head, flexible and simple operation, no need for professional welding technology, suitable for small batch and large batch production and processing, widely used in sheet metal processing, cabinet kitchenware, chassis cabinets, staircase handrails, elevator escalators, display shelves, doors and windows, advertising models, distribution boxes, stainless steel home crafts and gifts, household and other complex and irregular welding industry.

Item | Specification |

Product Name | Handheld Laser Welding Machine |

Laser Power | 1000W/1500W/2000W |

Laser Wavelength | 1064nm |

Fiber Core Diameter | 20μm |

Fiber Line Length | Standard 10m |

Working Method | Continuous/Modulated |

Galvanometer Width | 0-5mm |

Scanning Speed | ≤8000mm/s |

Welding Speed | 0-120mm/s |

Cooling Device | S&A Intelligent Dual-temperature Chiller |

Ambient Temperature Range | 15-35℃ |

Ambient Humidity Range | <70% No Condensation |

Working Voltage | 220V±10% |

Frequently Asked Questions (FAQ) – About Handheld Laser Welding Machines

Q: I don’t know which configuration is suitable for me ?

A: Please tell me

>> Your materials.

>> The thickness of your materials.

>> Size of welding line.

We will choose suitable machine for you.

Q: What payment terms can you accept?

A: Any payment is possible for us , like Made-In-Chine on line payment, TT, LC, Western Union, Paypal, E-Checking, Master Card, Cash etc.

Q: Do you have CE document and other documents for customs clearance?

A: Yes,we have, At first we will show you and after shipment we will give you CE/Packing list/Commercial Invoice/Proforma Invoice for customs clearance.

Q: When I got this machine, but I don’t know how to use it. What should I do?

We will send operation video and manual for the machines(Photos/Videos/Manual Book,etc) ,you can learn step by step. Our engineer also can do training online. If needed, we support engineer door training if you need.

Q: If i have problem during use,how to do?

A: If have any problem during use, we can provide team viewer/Whatsapp/Email/Phone/Skype with cam till all of your problems finished. We can also provide door service if you need.

Q: If some problems happen to this machine, what should I do?

A: We provide 2 years source and 1 year whole machine warranty. During the warranty, in case any problem for the machine, we will provide the parts free of charge (except for artificial damage). After the warranty, we still provide whole lifetime service. So any doubts, just let us know, we will give you solutions.

Q: What’s package, will it protect the products?

A: We have 3 layers package. For the outside, we adopt wooden cases free of fumigation. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic film.

Q: What’s delivery time?

A: Commonly, the lead time is within 3 working days after receiving the payment.

Q: How is the shipping method?

A: As per your actual address, we support shipment by sea, by air, by truck or railway shipping way. Also we can send the machine to your office if you need.

Factory Show