Wood is an ideal material for laser engraving and laser cutting due to its natural properties and ability to produce precise, detailed results. The focused heat of a laser beam can remove layers of wood with accuracy, allowing for the creation of intricate engravings and complex cuts that are difficult to achieve with conventional woodworking methods such as sawing or milling. This precision eliminates the need for post-processing, as laser cutting produces clean edges without leaving chips or sawdust.

Functionality

When laser cutting wood, the temperature within the laser’s path rises above the sublimation point of the wood, vaporizing the material. This vapor is carried away as smoke, dissipating the heat and preventing damage to the surrounding area. However, depending on the wood type, a slight brownish discoloration may appear along the edges. The speed and quality of processing are influenced by factors such as wood density and resin content, with softer woods generally cutting faster.

Laser engraving operates similarly, but the grain of the wood plays a crucial role in the appearance of the final product. For example, low-fiber woods like beech, cherry, or poplar offer consistent, high-contrast engravings, while high-fiber woods like bamboo tend to produce less refined results. Engravings on lighter woods such as birch or poplar tend to have a subtle appearance, whereas hardwoods like oak or beech provide darker, more pronounced engravings. Applying a glaze or finish afterward can further enhance the contrast and depth of the engraving.

Applications

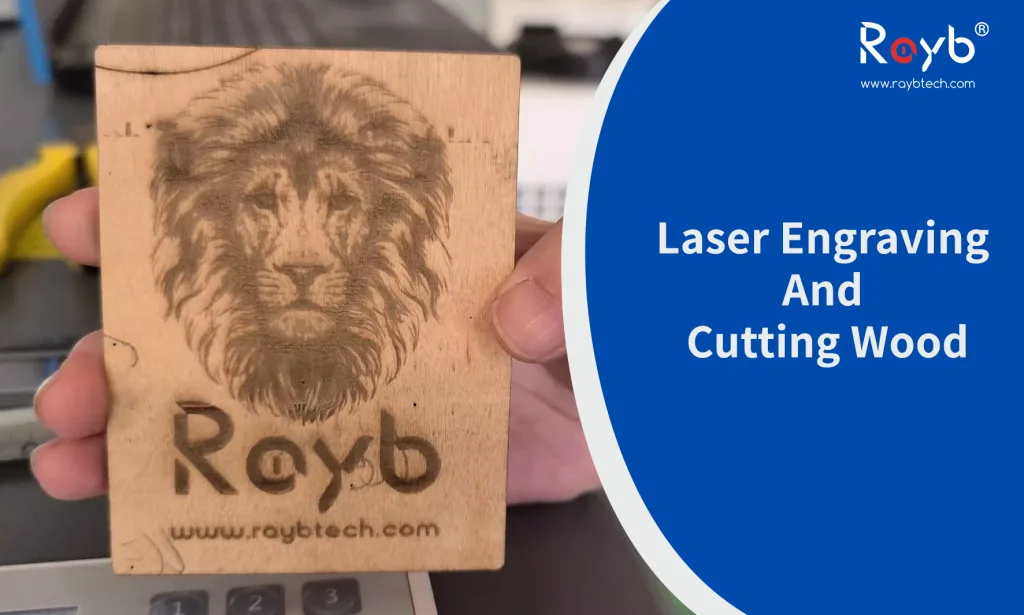

Laser engraving and cutting open up a world of creative possibilities when working with wood. From engraving personalized text, logos, and designs on photo frames, cutting boards, and even musical instruments, to cutting out detailed product parts for toys, decorations, architectural models, and more, the applications are broad and flexible. Engraving on veneered or lacquered wood is especially impactful, as the laser can remove the top layer to reveal the material underneath, resulting in striking visual effects. Laser cutting allows for the precise creation of custom parts and decorations, including Christmas ornaments, souvenirs, and inlays for furniture or handicrafts.

Advantages:

- Clean and efficient processing: Laser technology eliminates sawdust or chips.

- High precision: Achieves intricate cuts and engravings that traditional tools cannot.

- No need for post-processing: No additional sanding, filing, or finishing is required after laser cutting.

- Cost-effective: Avoids the need for expensive tools like saws, routers, or milling machines.

- Versatile: Works with a wide variety of woods, from soft to hard, and delivers consistent results.

In conclusion, laser technology offers a highly efficient, clean, and precise method for processing wood, making it an invaluable tool in industries ranging from furniture making and crafts to architectural modeling and product design. Its flexibility allows for high-quality results without the mess or manual labor associated with traditional woodworking techniques, all while enabling rapid production and superior detailing.