Laser marking is extensively utilized across various fields and industries, with one of the most common and beneficial applications being the marking of electronic components. The continuous advancements in technology have led to an increasing demand for efficient marking systems. Here’s how laser technology can enhance your company’s electronic laser marking needs.

Versatility of Laser Fiber Optic Systems

Laser marking for electronics predominantly employs laser fiber optic systems due to their high versatility. These systems are ideal for marking electronic components made from a wide range of materials, including:

- ABS plastics

- Glass-filled plastics

- Polythene plastics

- Various additional plastics

- Carbides

- PCD

- Various synthetic materials

- Aluminium

- Anodized aluminium

- Brass

- Copper

- Steel

- Stainless steel

- Titan

- Nickel-plated materials

- Galvanised materials

- Black oxide

- Painted materials

- Various coated materials

This extensive range of compatible materials makes laser marking a highly adaptable solution for electronic production.

Applications in Electronics

Laser marking systems are essential in various electronic industries. Products commonly marked with laser systems include:

- Mobile phones and smartphones

- Laptops

- Tablet PCs

- MP3 players

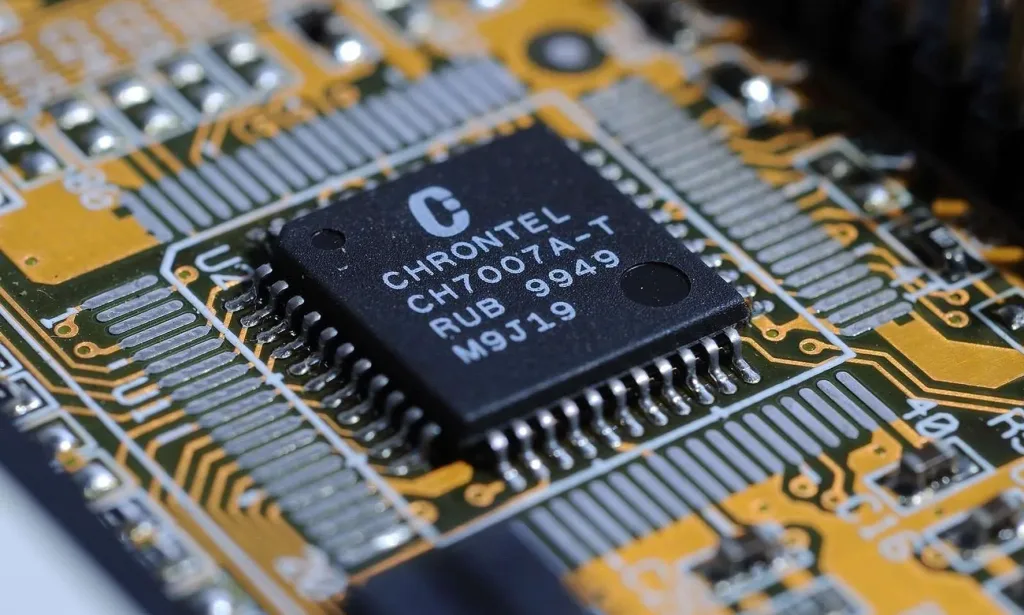

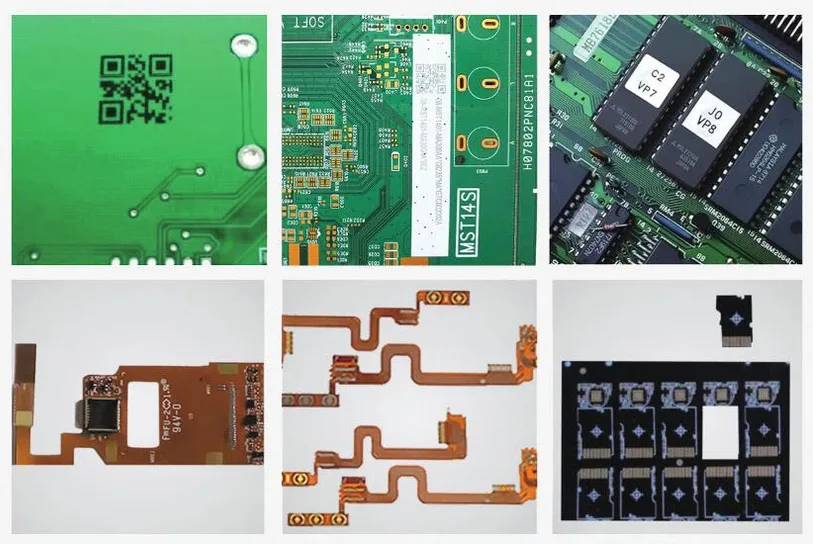

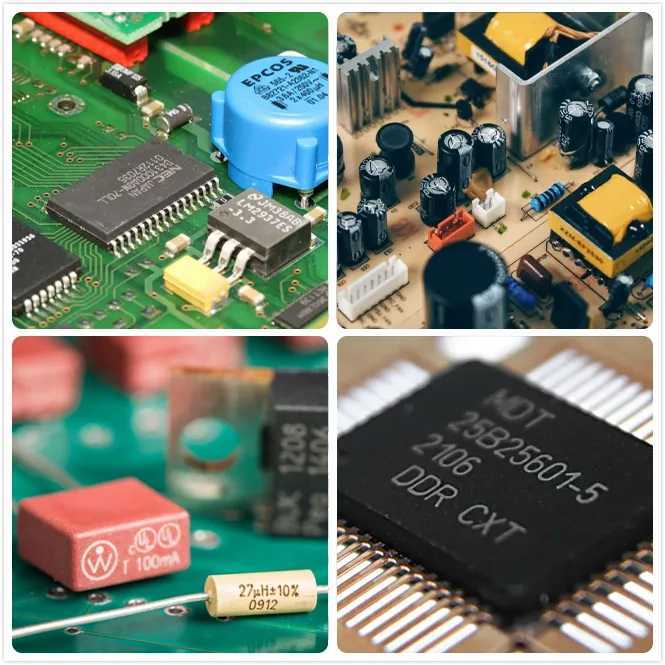

- Circuit boards / PCBs

- IC chips

- Silicon wafers

- Moulded plastic housings

- Automatic switches

- Semiconductor parts

- Product bins

For these products, laser marking systems provide several advantages:

- High-quality identification information for certificates, product specifications, barcodes, alphanumeric, and 2D codes.

- Ablation of copper and other materials.

- Kapton ablation and removal.

- Ability to mark information on small elements.

- Traceability of essential equipment.

- Durable, solder-resistant, machine-readable markings.

- Stylish company and product logos.

- Trimming of resistance.

- Assistance in quality assurance and trademark protection.

- Accelerated production time and increased productivity.

Laser marking systems produce clear, high-contrast characters without causing electrical interference, a crucial factor for electronic components.

Advantages Over Traditional Methods

Laser marking surpasses traditional methods such as pad printing, embossing, chemical etching, and screen printing in terms of cost, efficiency, performance, and precision. This makes laser marking the superior choice for modern electronic manufacturing.

Innovative Applications

The electronic laser industry continues to evolve, bringing new opportunities and applications:

- Data Crystal Storage: Enables the storage of vast amounts of data on glass coin-sized discs, estimated to last 13.8 billion years.

- Super Hydrophobic Surfaces: Scientists have developed laser-created surfaces ideal for electronic components, potentially revolutionizing smartphone construction.

We offer a wide range of laser marking systems for a wide range of industries. Our products come in different sizes, flexible workspace configurations and many useful features. To learn more about our solutions, please visit our website.