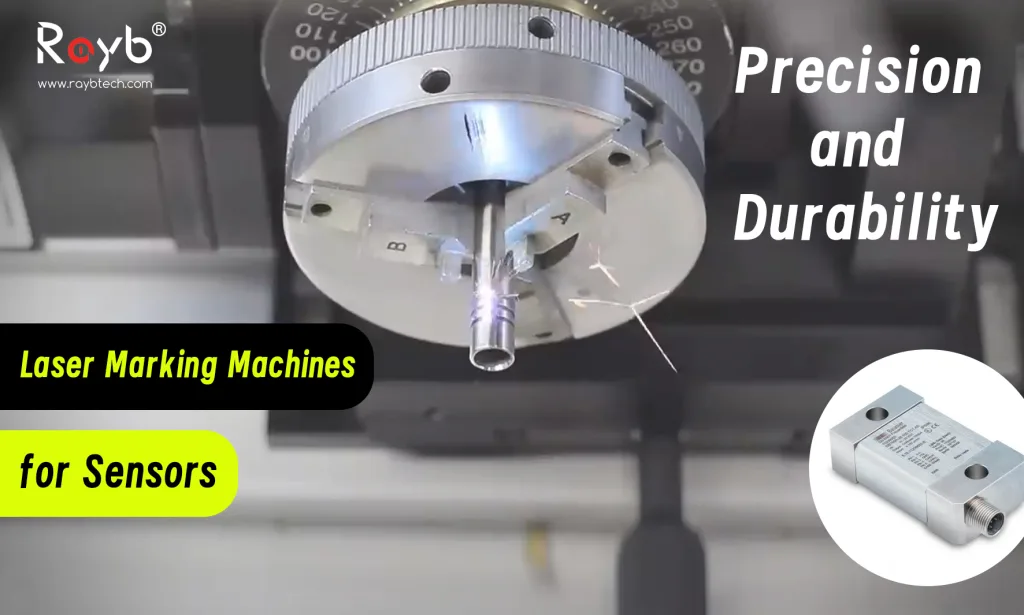

Introduction to Fiber Laser Marking for Sensors

Fiber laser marking machines are highly versatile and capable of marking a wide range of materials and components, including sensors. They are frequently used to engrave product models, logos, technical parameters, complex logos, and even QR codes on sensors. The fiber laser’s precision allows for high-quality, permanent marks that are easily visible without the need for additional tools, ensuring efficient identification and tracking.

Key Features of Fiber Laser Marking on Sensors

1.High Precision Engraving:

- Fiber laser marking delivers sharp, clear marks with a line width as small as 0.04mm, making it possible to engrave large amounts of detailed information on very small sensor components.

2.Non-Destructive Process:

- The marking process vaporizes the material’s surface with instantaneous high temperatures, without damaging the underlying sensor or causing defects such as cracks or fried borders.

3.Clear and Durable Marks:

- Laser marking produces marks with flush edges and minimal depth, ensuring clarity and readability. The markings are highly resistant to wear, corrosion, and environmental damage, allowing them to last as long as the sensor itself.

Applications of Fiber Laser Marking for Sensors

Sensors are essential components in modern technology, playing a critical role in data collection for industrial production and everyday life. They are used in a variety of fields, including:

- Automotive: For marking sensors in cars for systems like fuel monitoring, tire pressure, or emission control.

- Medical Devices: Ensuring that sensor components used in medical equipment and diagnostics are properly identified and traceable.

- Manufacturing: Sensors used in automated machinery can be laser marked with data such as serial numbers, batch codes, and calibration information.

- Consumer Electronics: Digital cameras, microphones, and household appliances use sensors that benefit from clear, long-lasting laser markings.

Advantages of Laser Marking for Sensors

1.Adaptability to Complex Surfaces:

- One of the most significant advantages of fiber laser marking machines is their ability to mark on both flat and curved or irregular surfaces. Even uneven sensor bodies can be marked with ease.

2.Enhanced Anti-Counterfeiting Measures:

- The ability to engrave complex graphics, QR codes, and serial numbers helps with product identification and tracking, reducing the risk of counterfeit parts.

3.Promotion and Branding:

- Clear and high-quality marks help promote brand visibility and convey a sense of professionalism and reliability in products.

Conclusion

Fiber laser marking machines offer powerful, reliable, and precise solutions for marking sensors. The marks are durable, legible, and resistant to external factors, which is crucial for the long-term performance of sensors in various industries. With the ongoing development of laser marking technology, its applications in sensor processing continue to grow, bringing benefits in terms of speed, quality, and flexibility. The advancement of laser marking in this field is shaping the future of automated and high-precision sensor manufacturing.