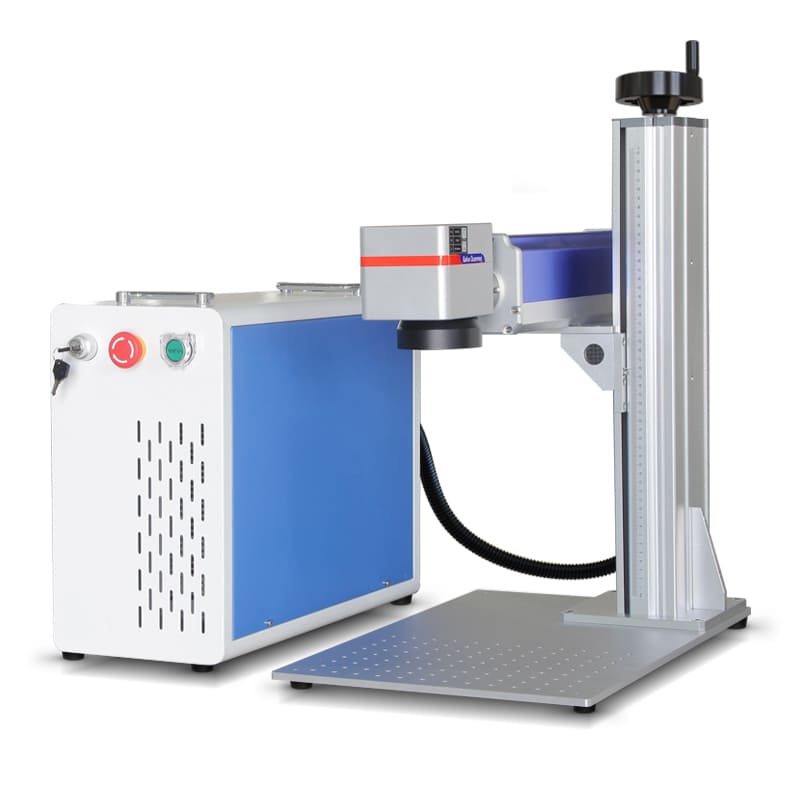

Precision Fiber Laser Cutting Machine 1000w 1500w 2000w 3000w 4000w 6000w Metal Precision Laser Cutter

- Laser Power: 1000w 1500w 2000w 3000w 4000w 6000w

- Laser Source: Raycus/Max/JPT/Bwt

- Cutting Materials: SS CS Aluminum Galvanized Sheet

- Size: 1470mm*1480mm*2050mm

- Machine weight: 1500kg

PRODUCT CATEGORIES

NEED CONSULTATION?

Share your idea, We’ll find solution for you within 24 hours

Precision Laser Cutting Machine Introduction >>>

Laser cutting uses a high-power density laser beam to quickly heat the material to vaporization temperature and evaporate to form a hole, move the beam to form a slit, so that realize the materials cutting .

Based on this ,Rayb Tech small area high precision cutting machine also achieves high-precision cutting, no tool wear, low heat impact, fast speed, automatic positioning, automatic correction and other functions.

It can be used for scribing, cutting and drilling various metal sheets and micro-precision metals. It is mainly used in LED, precision machinery, semiconductor control devices, 3C parts industry, and precision processing of handicrafts.

Advantages of Precision Laser Cutting Machine >>>

★ The integrated design of the granite stone 00 grade marble platform frame is reasonable, safe and reliable;

★ Using advanced fiber laser source, it has good beam quality, high electro-optical conversion efficiency, stable performance, no reflective lenses, no need to adjust the optical path, which can greatly save energy consumption during work, extremely low operating costs, basically maintenance-free, and a service life of up to 100,000 hours;

★ Fixed optical path design, maintenance-free optical path, low operating cost, good cutting quality and high processing efficiency;

★ The cutting head adopts capacitive sensing design, which has high sensing accuracy, sensitive response, and stable and reliable performance;

★ The CNC system adopts a dedicated laser control system and a non-contact height tracking system, which is sensitive and accurate, is not affected by the shape of the workpiece, and can process any graphics;

★ And professional CAM software, with powerful functions, stable operation, simple operation and easy to learn;

★ The machine tool adopts CNC structure, and the body adopts an integral welded structure, which undergoes vibration aging treatment, which can completely eliminate welding and processing stress, and has the advantages of good rigidity, high precision, and no deformation;

★ The guide rail adopts fully enclosed protection to reduce dust pollution, high-precision linear motor transmission, and imported high-precision linear guide rail guidance;

★ You can design various graphics or text for instant cutting, the operation is simple, flexible and convenient; the cutting edge is smooth and flat, the cutting heating area is small, and it is not easy to deform.

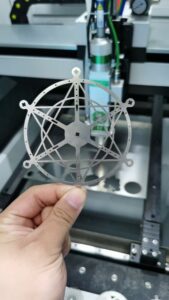

Samples of precision fiber laser cutter >>>

ITEM | PARAMETER | DETAIL |

Speed | X/Y axis maximum positioning speed | 60m/min |

| X/Y axis maximum acceleration | 1.5G |

Cutting parameters | Incision width | 0.05-0.15mm (depending on the thickness of the board) |

| Cut roughness | Ra3.2-25.4um |

| Cutting plate thickness range | ≤8mm |

| Minimum setting unit | 0.1mm |

Laser parameters | Laser wavelength | 1064nm-1080nm |

| Laser power | 1000W |

Transmission mode | linear motor | dual drive magnetic levitation linear motor |

Power supply parameters | phases | Three phases |

| Power supply rated voltage/frequency | 380/220V 50Hz |

| Total installed power consumption | 10KW |

| Overall power protection level | IP54 |

Weight and Dimensions | Maximum load capacity of workbench | 200kg |

| Machine weight | 1500kg |

| Machine size (L/W/H) | 1470mm*1480mm*2050mm |

Processing format And working range | processing format (L/W) | 600mmx600mm |

| X-axis travel | 610mm |

| Y-axis travel | 610mm |

| Z axis travel | 50mm |

Accuracy | Equipment accuracy | +/-0.03mm |

| X/Y axis geometric positioning accuracy | ≤0.008mm (full range) |

| X/Y axis repeat positioning accuracy | ≤0.008mm |

Factory Show