Marking machines have become indispensable tools for various industries, capable of marking a wide range of materials from plastics and leathers to metals and glass. Among them, UV and Q-switched fiber lasers stand out as popular choices. But what sets them apart, and why does one often come with a higher price tag? Let’s delve into the distinctions between these two technologies and explore their primary applications.

Similar Appearance, Different Cores for fiber laser marking and UV laser marking machine.

At first glance, UV and fiber laser machines might look identical. However, the technology that powers them is markedly different. The fiber laser operates on a distinct laser source compared to the UV laser. Additionally, while UV lasers require water cooling to function, fiber lasers can be air-cooled, making them more accessible in terms of maintenance and setup.

Tailored for Specific Materials

Each machine is designed with a specific set of materials in mind. The fiber laser engraving machine is the go-to choice for metal engraving, offering solutions for metal marking industries. It can etch, engrave, or even sculpt with depth on metals. Conversely, the UV laser is crafted to be an all-rounder, particularly adept at marking plastics and glass. It can engrave a vast array of materials, from metals to paper.

A Comprehensive List of UV Laser Capabilities

The UV laser’s applications:

– Branding on some metals

– Engraving and marking on all plastics

– Glass branding and etching

– Marking on certain types of stone

– Paper marking and etching

– Leather marking and etching

– Fruit branding

– Wood branding

– Ceramics branding

– Clothing branding

For an exhaustive list, feel free to reach us.

Whatsapp: 0086 18863518575

Email: sales@raybtech.com

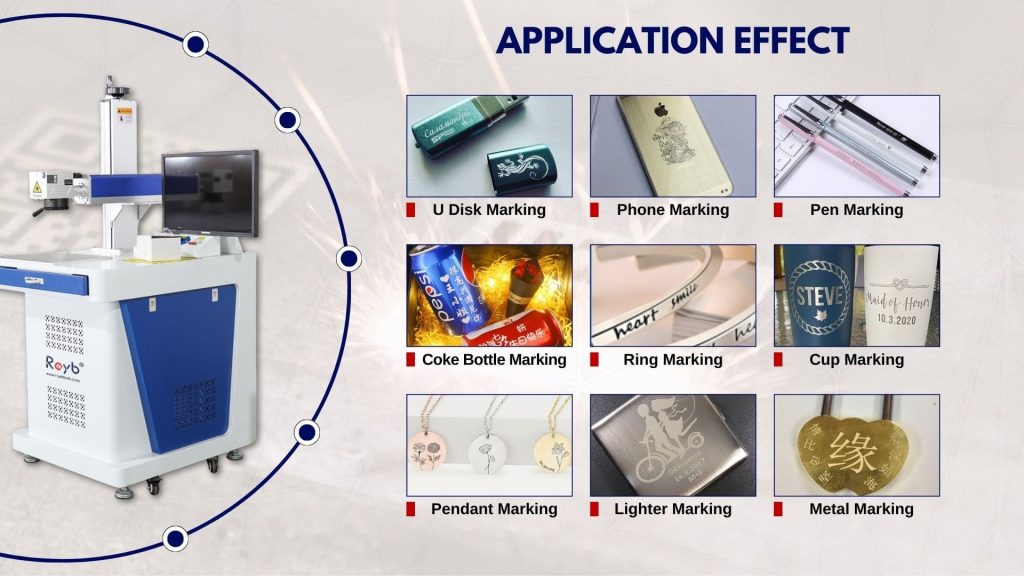

Fiber Lasers: Precision on Metals

Fiber lasers excel in:

– Etching and marking on all metals

– Marking on select plastics

– Branding on certain stones

– Marking on some skins

– Paper marking

– Garment branding

Interested in learning more about the materials these lasers can handle? Contact us for further details.

The Versatility of UV Lasers

While the UV laser can engrave more materials than its fiber counterpart, it falls short when it comes to engraving and carving on metallic materials. Here, the fiber laser’s capabilities shine, offering a significant advantage for those needing to mark, etch, and sculpt metal.

Advantages of UV Laser Technology

The UV laser’s main allure lies in its multifunctionality. It can engrave on a variety of products, including non-metallic ones. This technology is also compatible with automation systems such as rotary engraving, linear guide engraving, conveyor engraving systems, and cam capture systems.

Limitations of UV Lasers

A drawback of UV laser technology is its weaker performance on metals. For those seeking a machine that can deeply inscribe and carve metals, a fiber laser engraving machine is a superior option.

Fiber Laser Engraving: Speed and Depth

The fiber laser’s primary advantage is its ability to quickly and deeply etch, mark, and sculpt metal materials. While it can also mark various non-metallic materials, the results may not be as crisp as those achieved with a UV laser. Nevertheless, the fiber laser’s ability to work effectively on metals and some non-metallic materials is a significant plus.

Challenges with Fiber Lasers on Non-Metallic Materials

When it comes to engraving non-metallic products, the fiber laser’s limitations become apparent. It cannot etch or mark as wide a range of products as the UV laser. For instance, it can engrave ABS and PLA, common plastics found in many products, but there is a 5-10% melting point when using a fiber laser. This means that the engraved surface can feel warm to the touch, a sensation not experienced with UV laser engraving.

This revised text aims to provide a clear and concise overview of the differences between UV and fiber laser marking machines, their applications, and disadvantages of each technology.